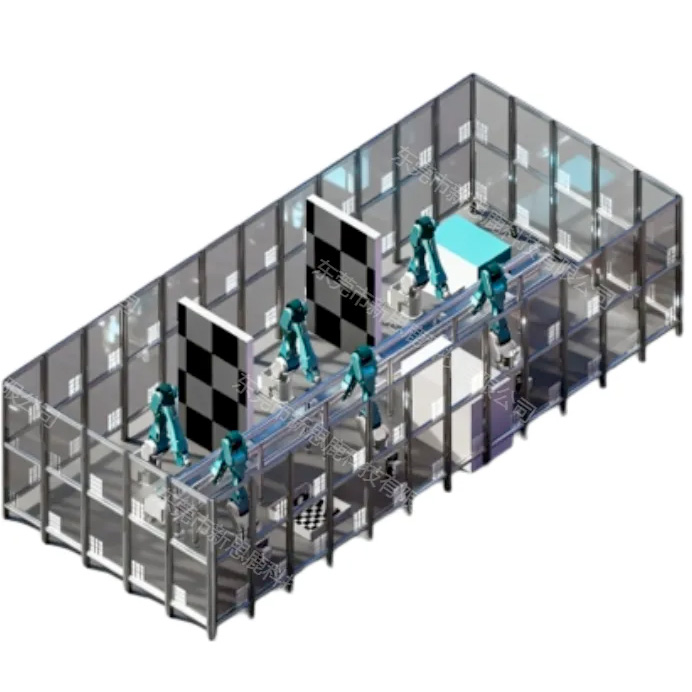

UAV Motor Assembly Line| 无人机电机组装线

Equipment Features

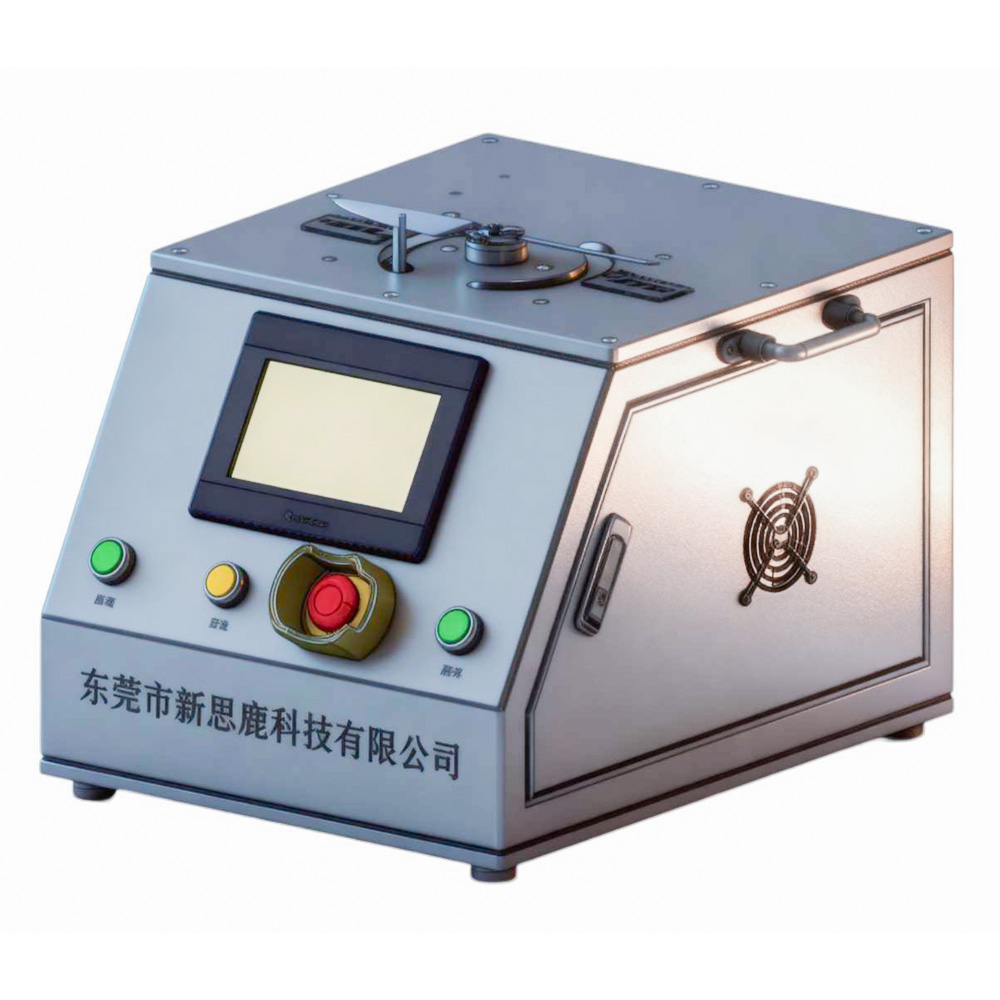

| Item | Specification |

|---|---|

| Standard Configuration | Vision-guided adhesive dispensing, servo press-fit system, high-precision magnet placement, constant-force preloading, high-accuracy testing, AI-based visual inspection |

| Applicable Motor Type | Outer-rotor motors |

| Cycle Time | 4–8 s / unit |

| Yield Rate | ≥99.8% |

| Loading / Unloading Method | Automatic |

| Control System | PC-based control |

| Overall Dimensions | W1000 × L6000 × H1800 mm |

| Equipment Weight | 1000 kg |

Description

Standard Configuration:

The UAV Motor Assembly Line launched by Dongguan Newleda Technology Co., Ltd. is designed for the fully automated assembly and testing of gimbal motors.

The line integrates multiple processes including adhesive dispensing, shaft assembly, rotor adhesive dispensing and rapid magnet insertion, stator assembly and preloading, visual inspection, and motor performance testing, providing a highly efficient and stable automated manufacturing solution.

|

|

Related Products

Reviews

There are no reviews yet.