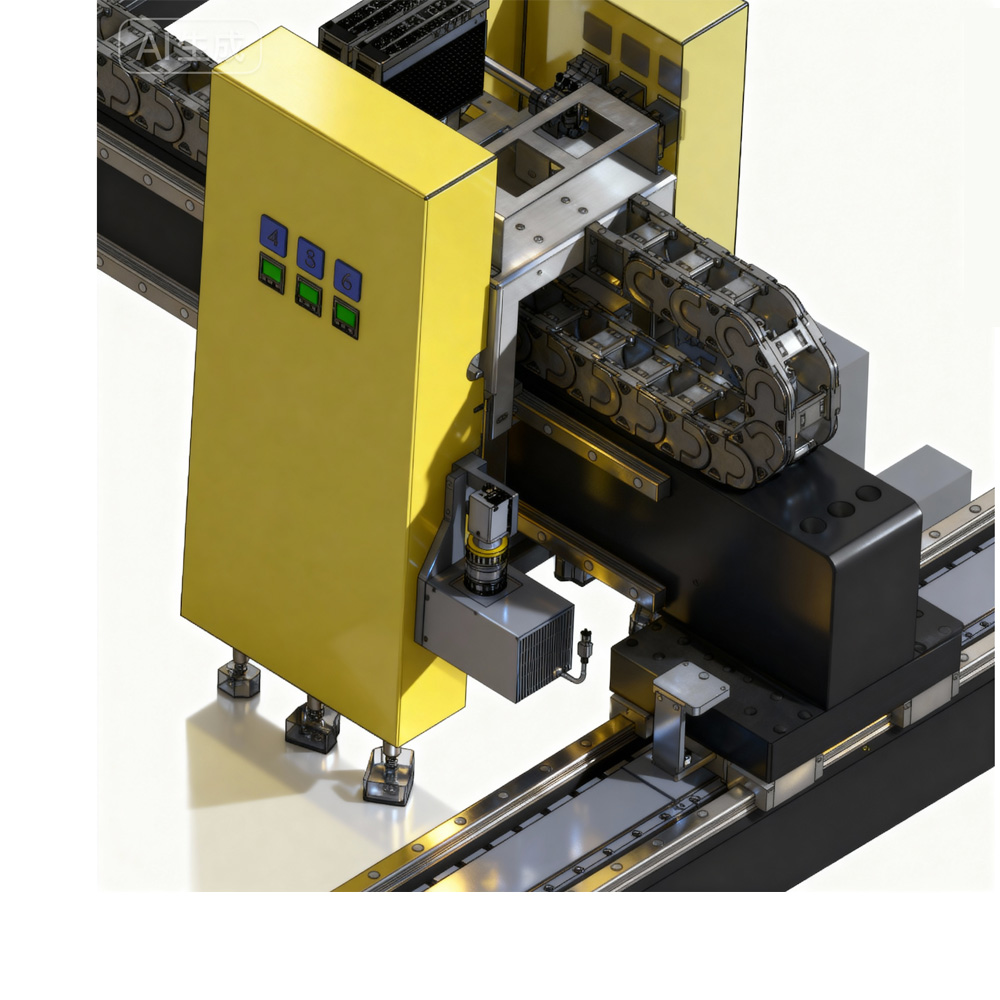

Auxiliary Material Placement Machine| 辅料贴装机

Equipment Features

The shield cover placement machine is designed for SMT post-process operations in smart-device manufacturing (such as mobile phones, home appliances, drone mainboards, and automotive GPS mainboards). It replaces manual operations for placing shield covers and similar auxiliary components at the end of SMT lines.

-

Supports loading of up to 6 different types of shield covers

-

Equipped with a multi-camera high-precision positioning control system, improving placement accuracy and speed

-

High-efficiency multi-axis placement head with 6 vacuum nozzles; placement speed up to 2.5 s/pc, yield rate ≥ 99.8%

-

High-precision transmission and positioning system using dual-drive gantry linear motor closed-loop control, significantly improving efficiency, accuracy, stability, and equipment service life

-

Optional barcode scanning and connection to MES and other data-processing systems

Description

Standard Configuration:

|

|

Related Products

Reviews

There are no reviews yet.