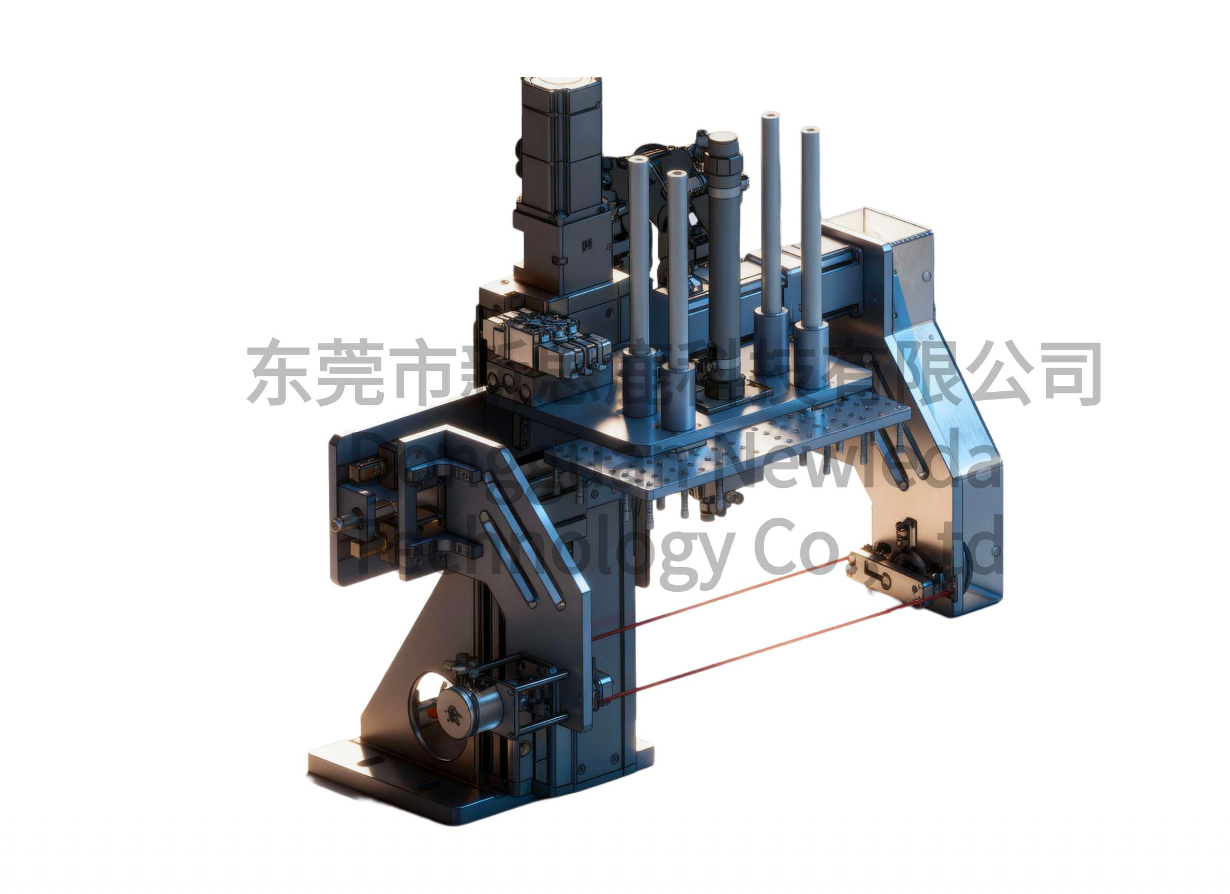

Automatic Flipping Machine|自动翻面机

Equipment Features

The automatic flipping machine is used for 180° fixture flipping. It can flip products (such as PCBA boards) to enable automated processing on both sides, making front-side and back-side operations easier to integrate in an automated line.

-

Supports both fully automatic and semi-automatic operation

-

Ball screw lifting module + precision rotation mechanism enables high-accuracy flipping

-

Flips the entire fixture in one cycle—all products in the fixture are flipped at once, ensuring high stability and high efficiency

-

Works with standardized fixtures for sensor-less / quick changeover

-

Semi-automatic production supported with dual start buttons and safety light curtain

-

Optional intelligent dispensing controller (with high-precision proportional valve, suitable for servo pressure-controlled dispensing applications)

Description

Standard Configuration:

Belt-type double-layer conveyor; flipping mechanism; lead screw lifting module; standardized fixture

|

|

Related Products

Reviews

There are no reviews yet.