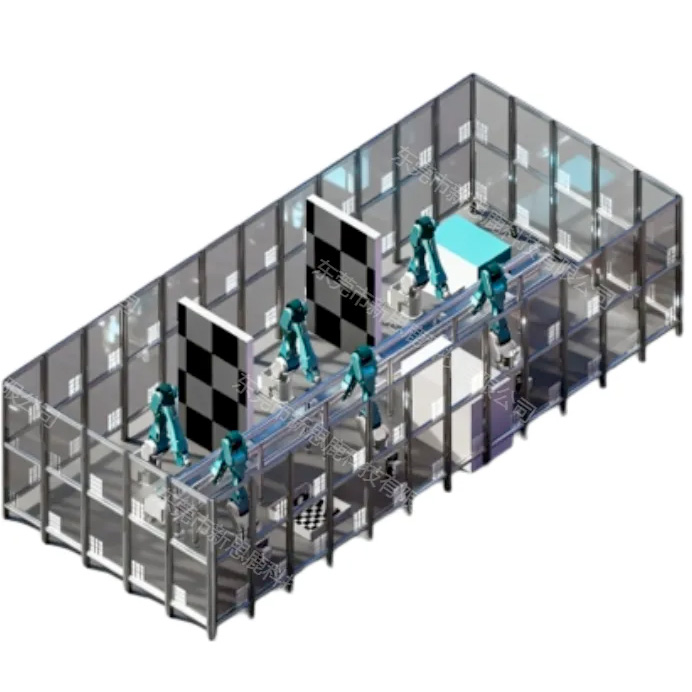

PCBA Assembly and Testing Line| PCBA组装测试线

Equipment Features

| Item | Specification |

|---|---|

| Standard Configuration | Belt-type dual-lane conveyor, vision-assisted auxiliary material placement machine, vision dispensing machine, shielding cover placement machine, flip mechanism, integrated heat sink assembly & fastening unit, lift mechanism, PCBA test station |

| Repeat Positioning Accuracy | ±0.01 mm |

| Throughput | 120 UPH |

| Yield Rate | ≥99.8% |

| PCBA Size | ≤100 × 300 mm |

| Auxiliary Material Size | 2 × 2 – 30 × 30 mm |

| Equipment Interface | Standard SMEMA |

| Feeder Quantity | 1–4 |

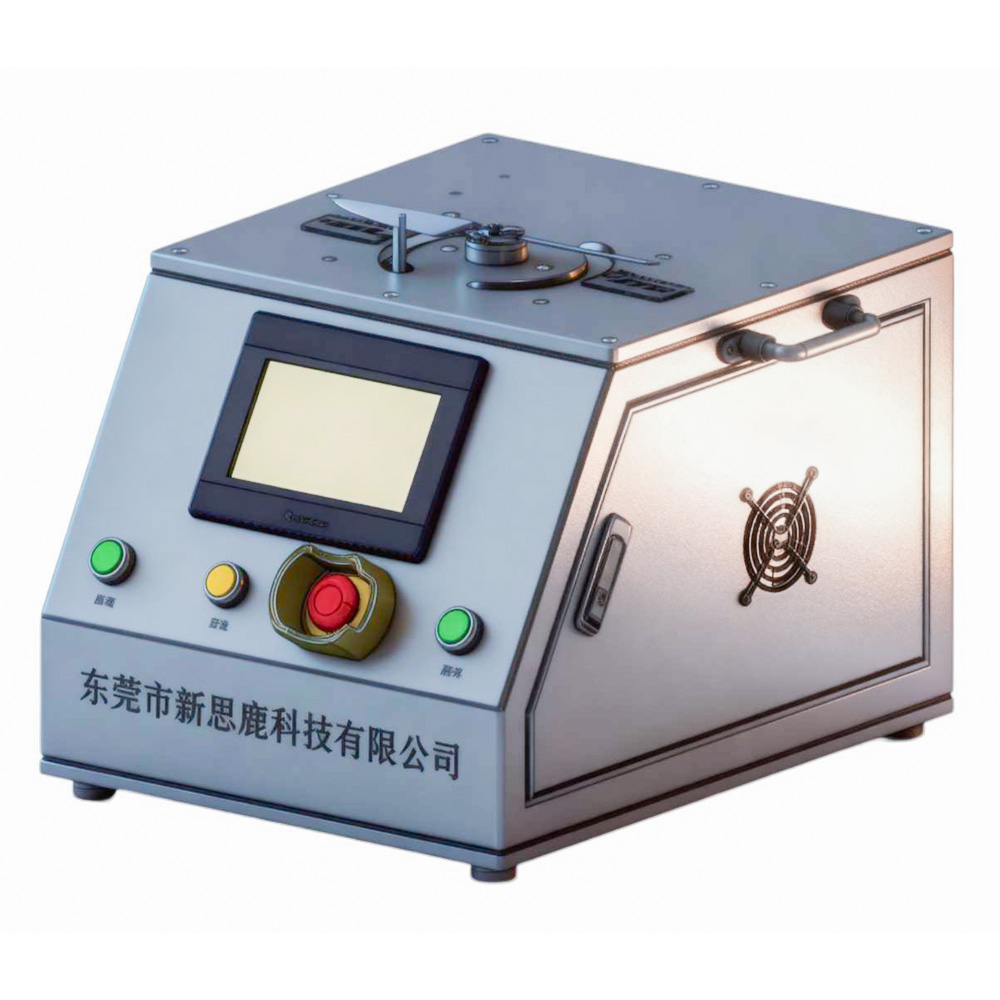

| Software | One-click model changeover, MES system integration, compatible with PCBA production lines |

Description

Standard Configuration:

The PCBA assembly and test line developed by Dongguan Newleda Technology Co., Ltd. is designed for post-PCBA assembly and testing of UAVs and other intelligent terminal devices.

The line supports multiple processes including thermal conductive adhesive dispensing (conformal coating, three-proof coating), conductive foam (cushion foam) placement, auxiliary material mounting, shielding cover installation, heat sink assembly and fastening, and functional testing, providing a highly automated and efficient production solution.

|

High-Speed, High-Precision Assembly Operations

|

Related Products

Reviews

There are no reviews yet.